N.T.M. SPA - Leader in Plumbing Fittings

About us

N.T.M. SPA is a leading Italian factory in the plumbing and sanitary fittings sector. Its production consists of brass fittings, manifolds, ball valves, cross-linked and multilayer polyethylene pipes.

Among the Italian companies in the sector, N.T.M. SPA is a very competitive reality and is present with its products both on the domestic and foreign markets in more than 50 countries.

Our History

The activity of N.T.M. SPA started in 1994 in Flero, in the province of Brescia, where it located its first production site of 3000 square metres. At the end of 2004, the company moved to Brandico, also in the province of Brescia, where it operates a 10,000 m2 production unit.

The name of N.T.M. SPA is linked to that of its founder Mario Tripoli and his family. Mario Tripoli and the current management staff of N.T.M. SPA boast the richest and longest experience (about 30 years) in the design and manufacture of brass fittings. In fact, he has been working in the sector since 1978, first with RB RACCORDERIE BRESCIANE SRL in Roncadelle and then, as a founding partner, with TIEMME RACCORDERIE SRL in Castegnato.

In practice, N.T.M. SPA, on the strength of this history, represents the evolution of the best previously achieved in the sector, assuring its customers the highest guarantee of quality obtained through the most advanced and tested technologies and the most innovative product ideas.

Production

NTM Spa is proud of its roots and has always ensured that the entire production cycle and its value chain are anchored in the territory. Every item produced by NTM is 100 % ‘MADE IN ITALY’.

All N.T.M. SPA production is controlled according to the ISO 9001:2008 production process and is approved by a wide range of certifications. N.T.M. SPA also checks that the raw material - brass alloy - corresponds both to the strict European standards UNI-EN12165CW617N and UNI-EN12165CW614N and to the standards against the radioactivity of materials, certifying that it comes only from authorised Italian factories.

Original N.T.M. SPA products are the only ones marked with the description ‘MADE IN ITALY’ on the body and/or on the nut and/or on the ogive, indications that guarantee their originality from possible counterfeits.

Design and Construction

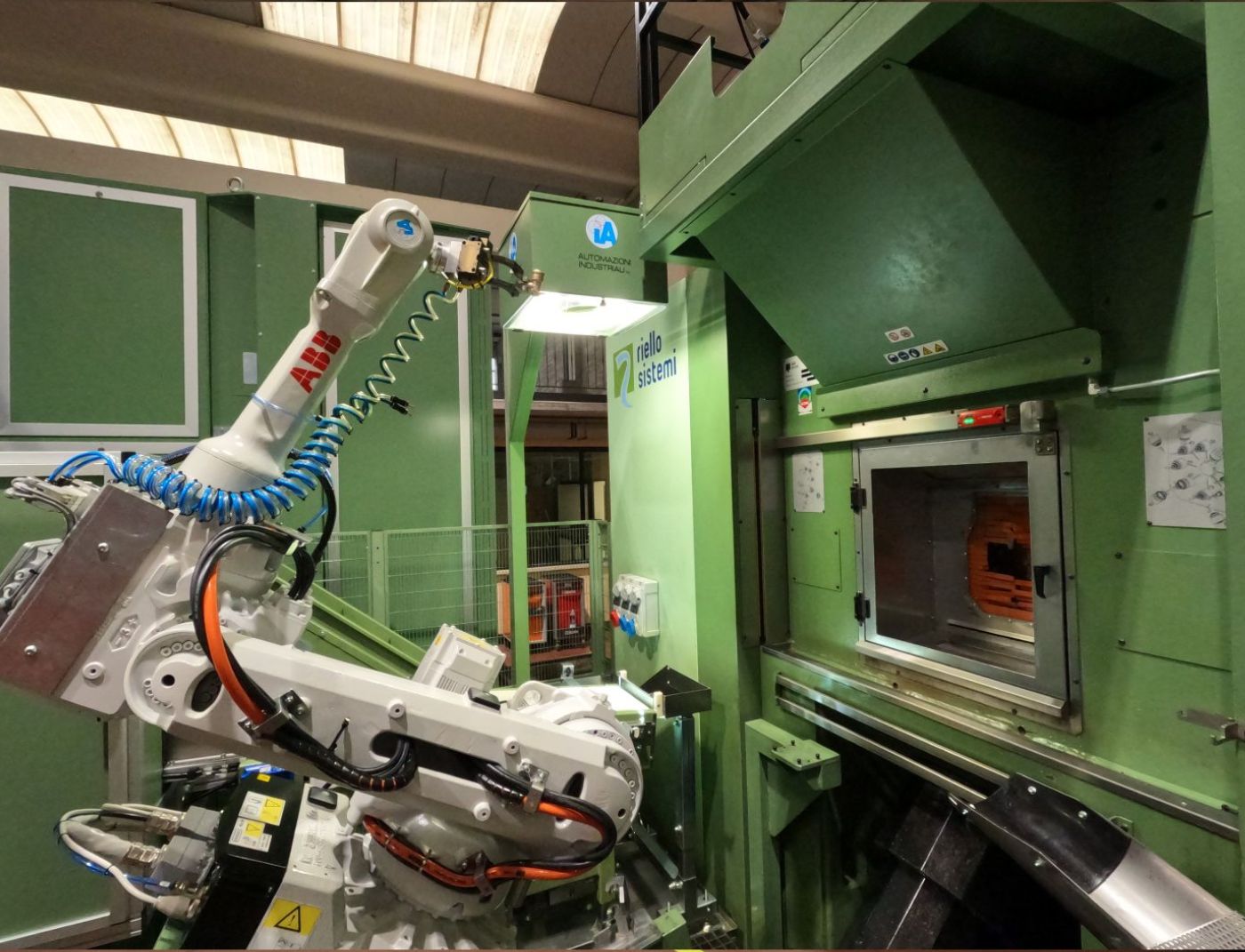

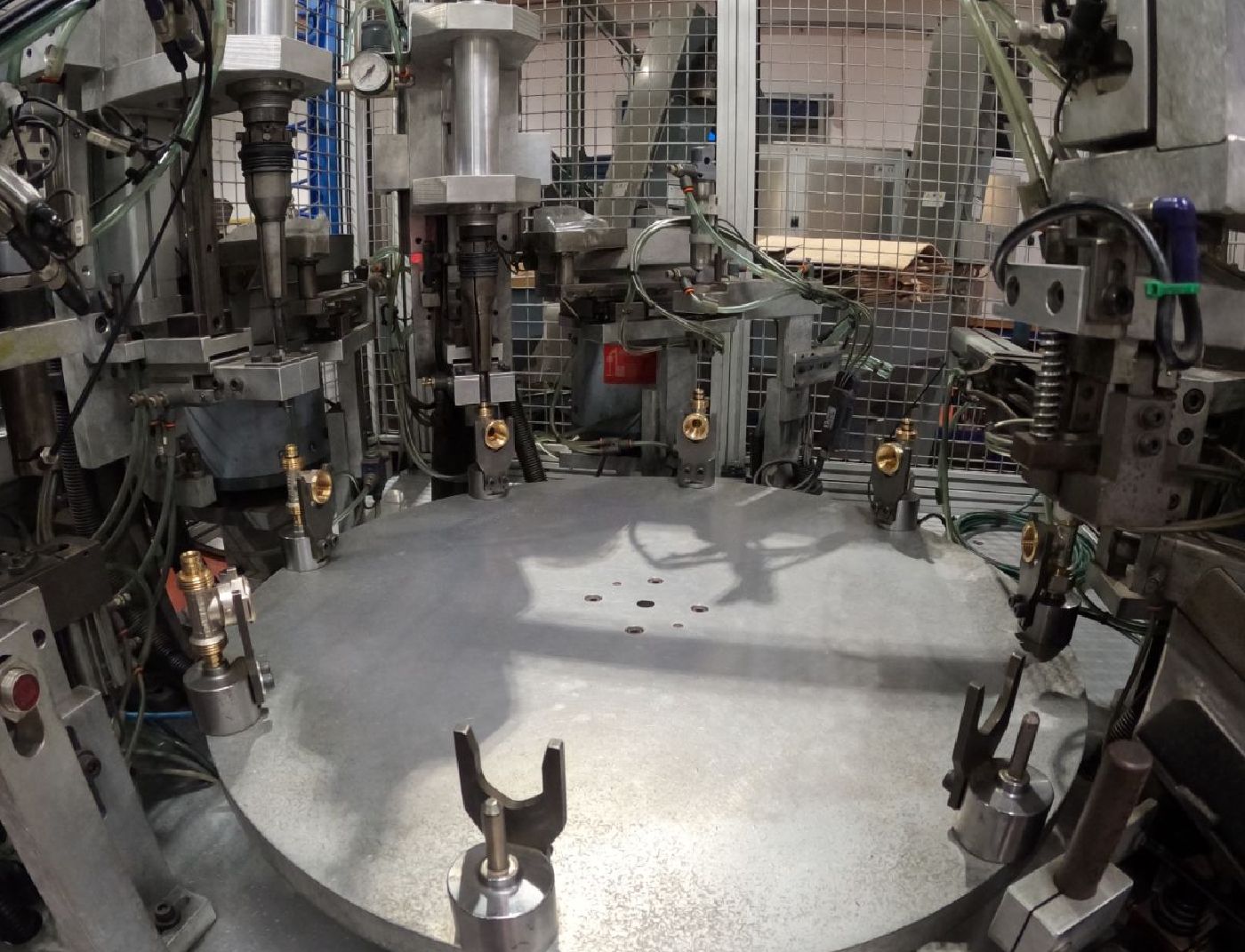

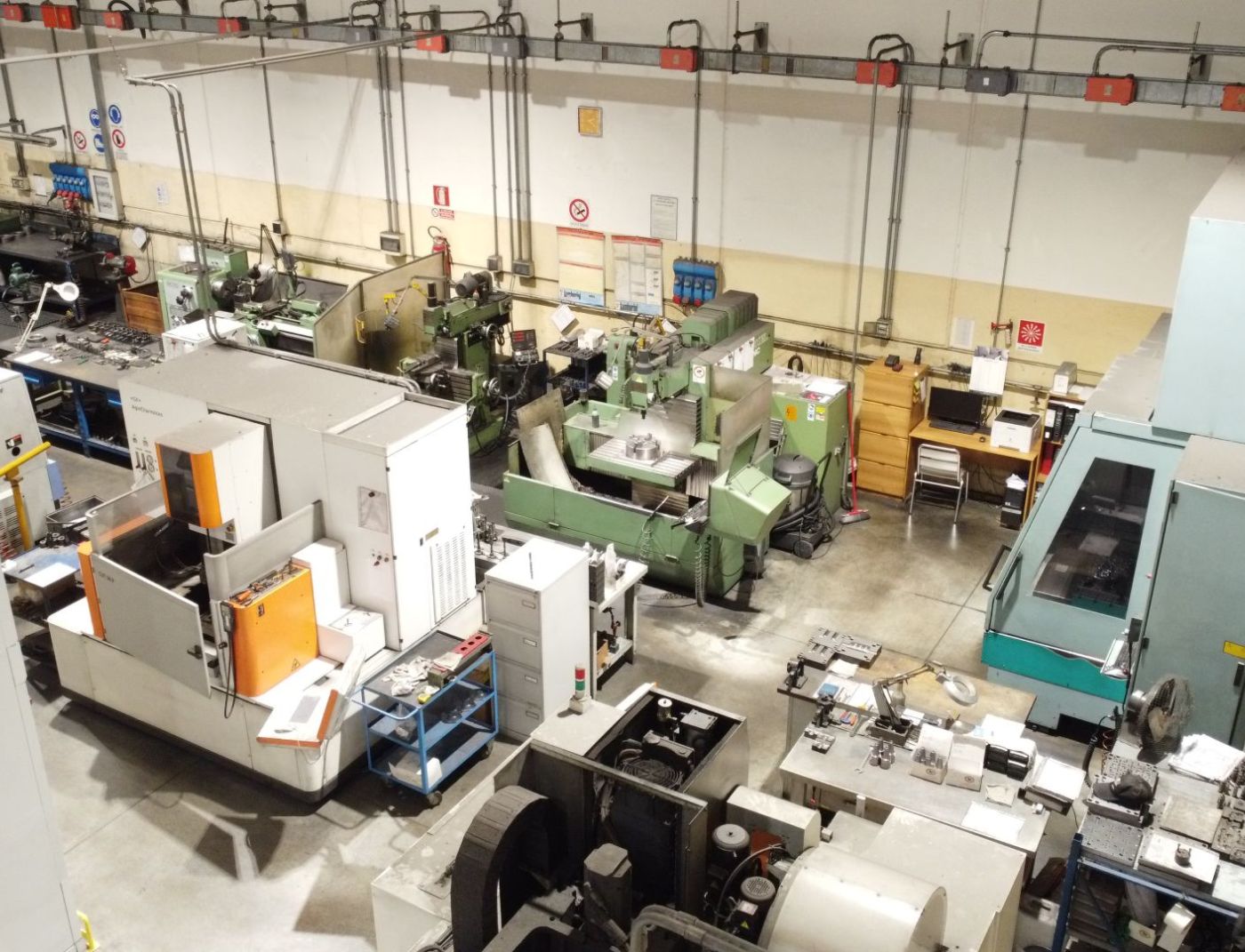

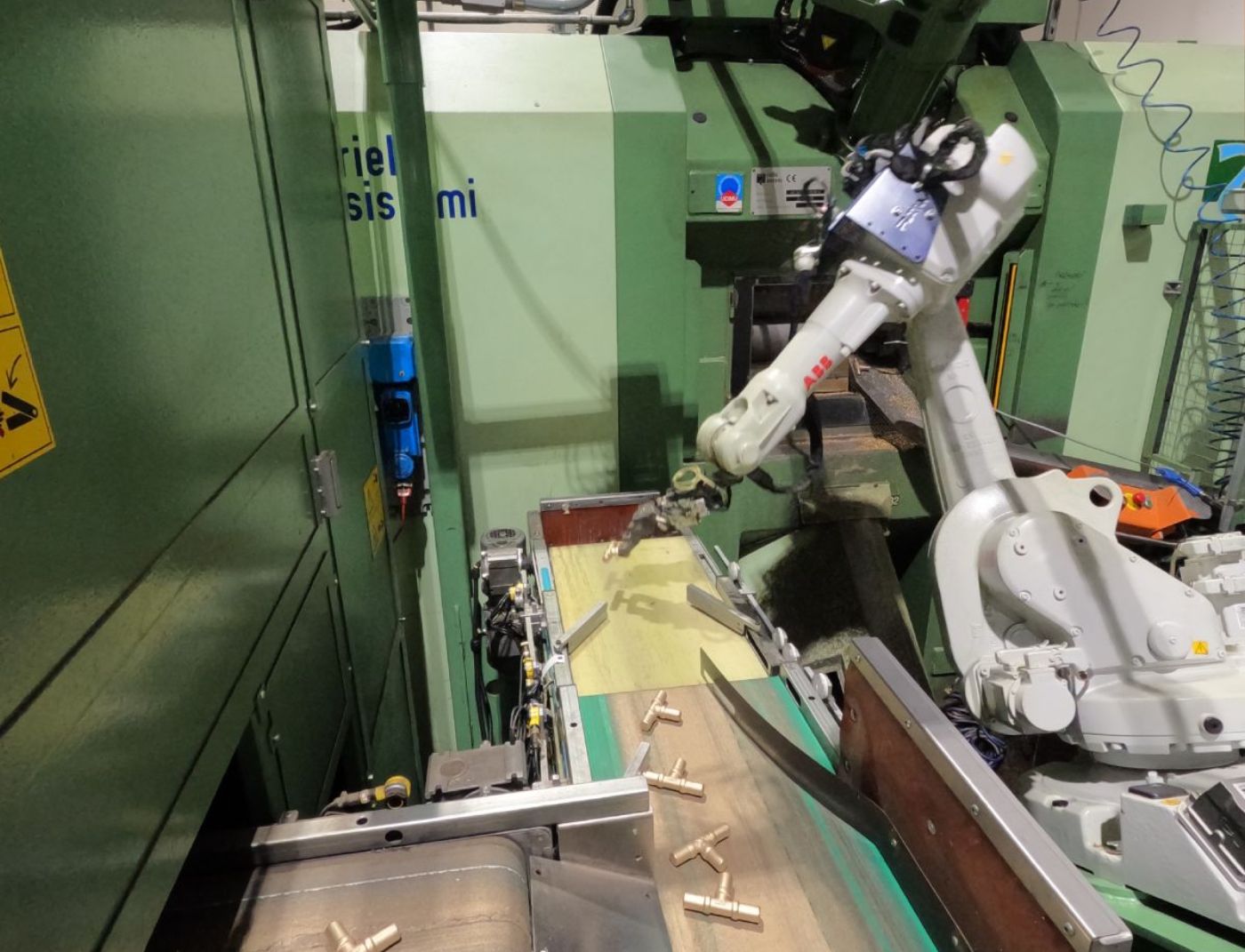

NTM valves and fittings are manufactured within a Quality System certified EN ISO 9001: 2008 with the most modern high-technology production plants for both hot moulding and mechanical machining and process automation. They are the result of a realisation cycle carried out completely in NTM, starting from the design up to their construction.

Dimensioning is carried out with the support of advanced computer tools: from 3D drawing to structural verification using FEA (Finite Elements Analysis) methods.

- Hot stamping

- Deburring of blanks

- Mechanical machining

- CAD-CAM process

The entirety of our production cycle enables us to fulfil every special request and to meet our customers' every challenge.

Visit Our Factory

Today, N.T.M. SPA is a constantly evolving company with a production capacity of approximately 200,000 fittings per day as well as a solid organisational structure that enables it to meet every customer requirement. N.T.M. SPA invites all its customers to visit its factory to see for themselves this entirely Italian reality.

---

N.T.M. SPA © 2024. All rights reserved.

Tel 0039 030 978971 r.a. - Fax 0039 030 9972157 e-mail: ntmspa@ntmspa.com